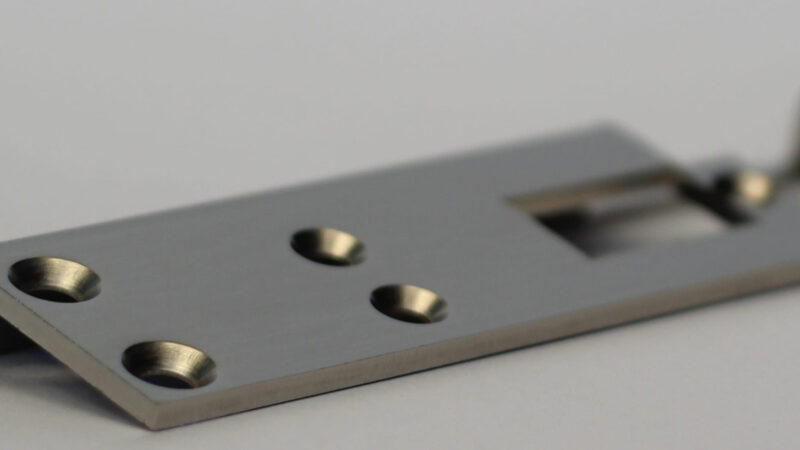

Alloy

We can help you choose the right alloy to improve the properties of your part and the cost of your project. Together we will find the match that gives your part the best results.

What is an alloy?

Alloying is a mixture of different substances to improve the properties of a metal. There are an infinite number of alloys, so choosing the right one can be difficult from both a technical and economic perspective. Alloys consist of one or more alloying elements, which can be metals as well as non-metals. Alloys are usually produced by mixing the components, but can also be produced by, for example, pressing, sintering or mechanical processing of materials. No more than small amounts of additives or small amounts of the constituent substances are needed to bring about major changes in the properties of the alloy.

Aluminium is often used, which is a light and strong metal with good resistance to corrosion and cracking. Mixed with small amounts of other metals, aluminium has a strength comparable to that of steel, while retaining its lightness and malleability.

Which alloy?

All alloys are developed for different purposes. It is rare that the materials are 100% pure, but the additives are intended to make the materials harder, softer, more malleable in a certain process and more corrosion resistant, etc.

If you are not sure which material to draw in your design, you can always ask us for advice. We are familiar with many of the alloys that are suitable for sheet metal processing.

Alloy - properties

- Increases metal hardness and strength

- Reduces corrosion in contact with water and air.

- Adapting the material to the manufacturing process for which it is intended, for example by softening the material.