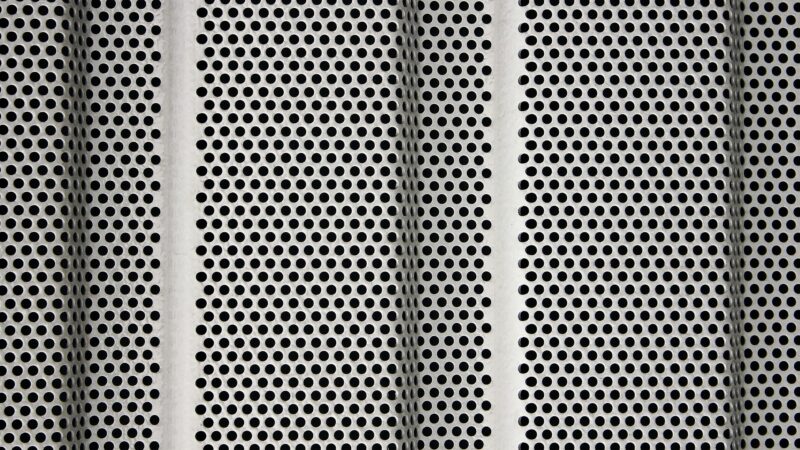

Punching of sheet metal

Through our punching machines, we have the flexibility to both make quick prototypes and to punch really high volumes.

Flexible punching of sheet metal

In our punching machines, we have a machine capacity of over 50,000 hours/year. This gives us the flexibility to both make quick prototypes and to punch out really high volumes. Several of our punching machines also have loading and unloading robots.

We perform stamping in Stockholm and can deliver stamped sheet metal to customers in the Stockholm area at short notice. We also deliver to customers throughout the country, as well as abroad. We also perform laser cutting in sheet metal and aluminium in combination machines, punch/laser.

We punch from about 0.5 mm up to 5 mm in aluminium, up to 2 mm in stainless steel and 4 mm in steel. Thicker materials are laser cut in our combination machines, which can also punch. The tolerance generally held is ISO 2768-m. See tolerance table here.

What is stamping and how does it work?

This method belongs to the shearing processing methods, which are divided into two main groups: shearing and punching. We also have burr shears for cutting sheet metal, which are suitable when you need to work quickly and have less stringent tolerance requirements.

Punching is an efficient method that involves using a cutting tool called a punch to push it through the material, with the desired shape of the hole, under the counter pressure of a pad. The punch and pad have sanded edges that correspond to the contours that the punched object will have. With punching, no unevenness or cracks should occur at the cut surface.

The punching tool is used to make holes in thin sheet materials, 0.5 mm - 4 mm material thickness. You can also nibble in punching machines, i.e. you punch out contours using many successive strokes. You get an entry side, the leading edge, on each hole and a burr side on the sheet, but we always deburr the burr side in one of our machines. fine machines adapted for this.

Don't hesitate - get in touch with your questions!

Do you have any questions about our services or products? Just get in touch with one of our competent employees!

Contact usPunching machine with CNC control

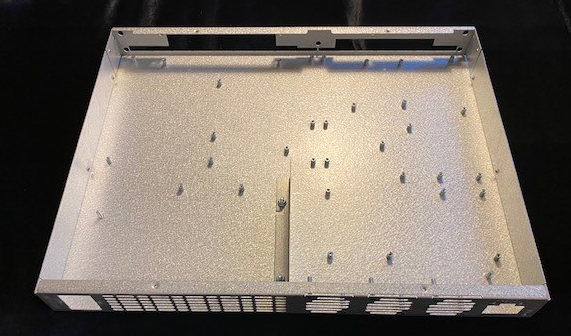

Punching has long existed as a method of punching holes and contours in sheet metal using punching tools. Nowadays the machines are CNC controlled, i.e. computerised. The process starts when a programmer has created a unique programme for each part to be manufactured, specifying the tools, the sequence and how the parts are to be placed on the sheet metal blanks. Next, the tools are set up in the machine and it is loaded with the correct sheet metal material.

Operator controls

We have routines for how we check the details, including through inspection, operator checks with measurements at the machine and also measurements in measuring machines or checks against equalisers. The result of punching is very precise - and in a short time. Experience is very important when working with punching machines. Every material is unique and can behave differently from batch to batch. This means that one manufacturing occasion is not always the same as another, and our experience plays a major role in the result. It is also important to know how the punching tools work and how the machine works. We have 40 years of experience in CNC punching and can promise the highest quality.

If you need sheet metal stamping, contact us at Plåt & Mekano Romator. We know sheet metal and stamping, you get safe products and good advice with short lead times at the right price.

Sheet metal punching with Plåt & Mekano Romator

- 40 years of experience in CNC punching machines

- One of the largest machine capacities in the Stockholm region - creating flexibility, speed and the possibility of large volumes.

- We also have a very large tool selection, which means we can do most things with existing tools.

- Five punching machines, two of which are automatic machines with loading robots, automatic punching machine with high stock loading and unloading robot.

- Production customisation - We help our customers find the right method and design in a cost-effective way.

- FAQ

- Knowledge article