Plåtbearbetning genom expertkunskap

Välj oss om du har höga krav på dina plåtprodukter, liksom på service och engagemang från din mekanikleverantör.

Plåtbearbetning från Täby

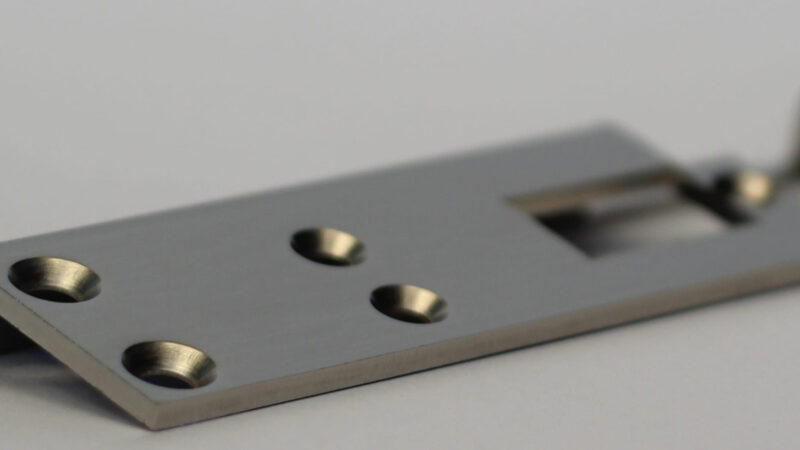

Plåt & Mekano Romator är ett legoföretag som arbetar med tunnplåt. Vi har i Täby samlat kompetens, maskinpark och verktyg från 2 väletablerade företag, Plåt & Mekano i Täby och Romator.

Sammanslagningen av bolagen har betytt att kunderna hos oss möter personer med mycket lång erfarenhet av plåtbearbetning och ges stora möjligheter att få fram prototyper och serietillverkade plåtprodukter snabbt och kostnadseffektivt. Välkommen till oss på Plåt & Mekano Romator!

För konstruktörer

Vi på Plåt & Mekano Romator har ofta täta samarbeten med våra kunder i deras utvecklingsprojekt. Vi har som leverantör av plåtbearbetning i flera decennier hjälpt kunder med konstruktion, produktionsanpassning och framtagning av ritning och prototyp.