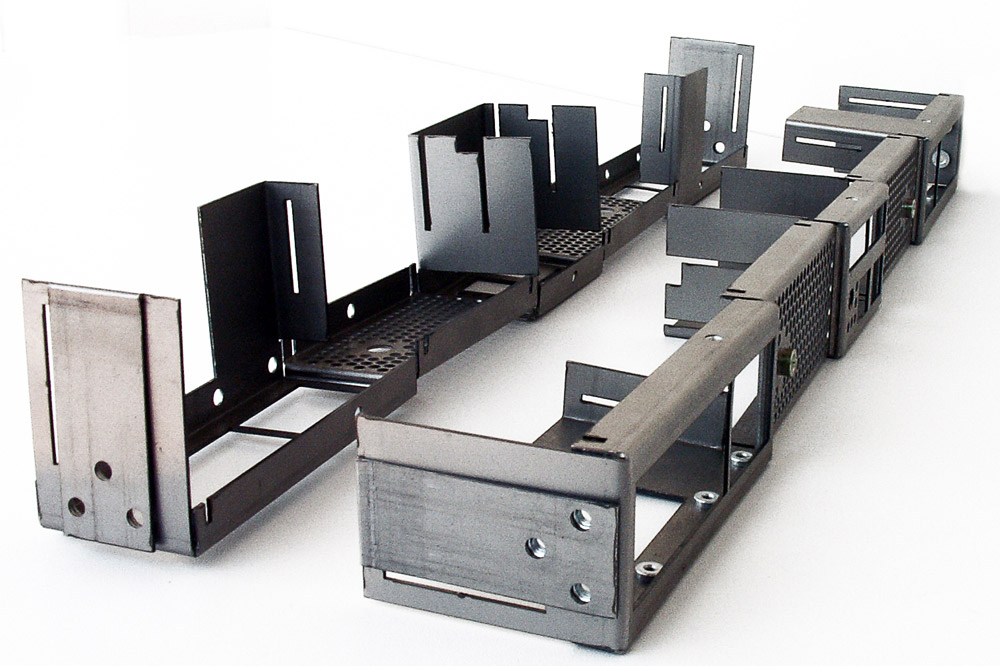

Our sheet metal processing

Quality, quality, quality. Whatever it is, we will deliver at the right level: high availability, delivery precision, and a personalized service.

Why choose us for sheet metal processing?

Plåt & Mekano Romator is a family-owned subcontractor in sheet metal processing. We have broad expertise, our own machinery, and tools from two well-established companies: Plåt & Mekano and Romator. Our skilled staff quickly fulfill your order, for small and large volume production, with our automated machines. With us, you get a final product that meets your high expectations!

Highest quality with the most modern technology

Our machines can handle materials from 0.3 mm - 6 mm thickness. We work in materials such as sheet metal, stainless steel, aluminum, aluzinc, magnelis, brass, copper and plastic, etc. Continuous investments in machinery, technology, and staff training keep us at the forefront of our industry.

We create flexibility when we have a dialogue with you as a customer about everything related to sheet metal processing in your project, from drawing issues to delivery. Our large capacity with both automated and manual machines, combined with our knowledgeable staff working in different shifts, results in flexible sheet metal processing that allows for shorter lead times.

Having said that, we believe that it is all this that keeps many customers coming back to us year after year, which we are very happy about. You are welcome to become our customer too!

Our services:

- Design assistance and drafting

- Prototype and series production

- Automated punching and laser cutting

- Laser cutting

- Welding in aluminium, steel and stainless steel

- Bending

- Assembling

- Other processing of sheet metal

- Plastic production