Knowledge bank

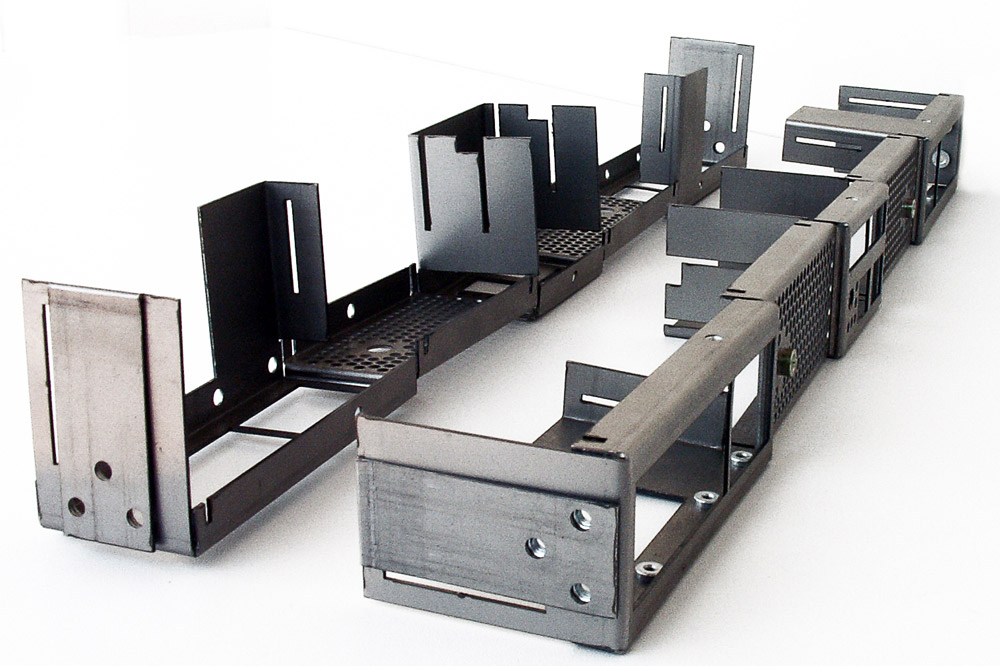

Choosing sheet metal processing to make parts in smaller series is a superior method if you need to modify the parts or if you want to utilise the unique properties of the material.

Sheet metal working

Thin sheet metal processing a superior method for small batches

Thanks to the malleability of sheet metal, there are endless possibilities to produce mechanical parts in the material. It is a superior material if you want to make parts in small series, if you need to redesign the parts for development projects, for example, or, of course, if you want to utilise its specific properties.

Imagination and tools can be the limit, but we will help you with your project to come up with the most economical solution possible. We have many years of experience and a very large set of tools at our disposal. In addition, we sometimes manufacture tools that we can use in customers' projects.

Advantages of sheet metal:

- Flexible material

- Many uses

- Easy to mould in many different ways

- Strong

- Impact resistant

- Temperature resistant

- Shields electromagnetic radiation

- Decorative

- Swedish produced, which means high quality steel.

- Recyclable

Don't hesitate - get in touch with your questions!

Do you have any questions about our services or products? Just get in touch with one of our competent employees!

Contact us

Different qualities and formats of sheet metal

Sheet metal is the actual format, the sheet, that the material comes in. There are an infinite number of sheet metal grades, in different alloys. The most common ones we work with are:

- Steel sheets, so-called 'ordinary sheets'.

- Aluminium sheet

- Stainless steel plate

- Brass plate

- Copper plate

- Aluzinc-coated sheet metal

- Galvanised sheet metal

- Magnelis

The discs can have different widths and lengths. They are rolled in steel mills to a certain thickness and slit to certain standard widths. They are then cut to suitable lengths. The formats that Plåt & Mekano Romator's machines can handle are up to 2500 x 1250 mm. Feel free to ask us about which qualities are suitable for your particular project. We have knowledge of which ones are commonly used and their prices.

What is defined as sheet metal?

What is defined as sheet metal is arbitrary. For example, some people and industries consider anything under 20 mm to be sheet metal. We at Plåt & Mekano Romator have chosen to define sheet metal according to what our machines can work with, i.e. from about 0.5 mm up to about 6 mm. After that we consider it to be coarser, but for some projects we can still work with this thickness.

We are experts in sheet metal processing

Plåt & Mekano Romator is a player to be reckoned with when it comes to sheet metal processing. We have been helping our customers for almost 45 years, mainly in areas such as electronics, telecom, medical technology, construction and property industry, industry and automation.

Often the project starts with a designer contacting us to discuss their idea or have a finished drawing. Sometimes we discuss a solution together and draw up a proposal for the customer to approve. We then make programmes for the machines, which the operator can then use to produce the prototype.

We can produce small and medium-sized series in volumes from 1 to 1000s. We can sometimes accommodate up to 100,000s of parts if needed for a start-up project.